Material Handling Systems

IBC - Intermediate Bin Containers

Intermediate Bin Containers (IBC)

IBC plays a very important role in the material movement in OSD manufacturing. IBCs are ideally used for storage, movement, and for mixing of powders, granules/pellets.

What differentiates us :

- Design ensures easy and efficient cleaning to avoid cross-contamination

- No sharp edges

- Designed ensures complete discharge, ensuring zero product retention

- Design angles ensure easy and smooth discharge of material

- MOC is SS 316 L

- Finish – Inside mirror and outside matt finish

- Bin can be stored/stacked one above other

- Can be easily handled with a manual forklift or forklift truck

- Usable volume from 30% to 70%

- Manual butterfly valve for smooth discharge

- Various sizes from 200 L to 2500 L can be offered

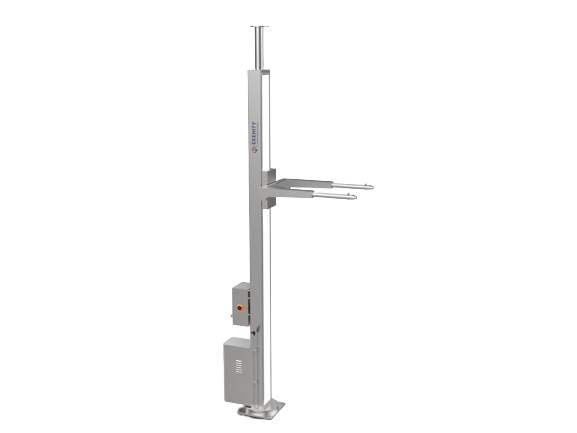

Lifting Tilting and Lifting and Positioning ces

Lifting and positioning, lifting and tilting are crucial in powder, granules, pellets, tablets, capsule loading, and unloading at various stages in OSD production.

Lifting and tilting ces are normally used to unload products from fluidized beds (either granules or pellets). Exenity can offer innovative design with multi-mill mounted on column. With this design, granules can be directly passed through the dry mill and collected in IBC.

Lifting and positioning ces can be used for :

- Loading of powders in High Shear mixer granulators

- Loading of powders in Sifter

- Loading of granules/pellets in tableting machines

- Loading of tablets in tablet coating machines

- Loading of granules/pellets/tablets in encapsulation machines

- Loading of tablets in blister machines

Vaccum Transfer Systems

With increasing awareness about operators/users’ safety and dust-free operating environment, the need for close loop vacuum transfer systems is increasing in OSD production areas. Exenity is equipped to offer you very efficient transfer systems for the following applications

- Loading of Sifters

- Loading of High Shear mixer granulators

- Unloading of Fluid beds

- Loading of encapsulation machines

- Loading of Tablet compression machines

- Loading of blenders, and many more

Exenity offers unique advantages for your vacuum transfer requirements

- Higher transfer rates up to 25 kg/minute to 30 kg/minutes

- Suitable for 2 Bar as well as 12 Bar pressure shock designs

- Easy to clean hoses

- Inbuilt WIP nozzles

- Buffer vessels are provided where ever necessary